August 26, 2015, was, by all accounts, a stressful day at Blue Apron’s facility in Richmond, California.

As the sun rose over what would be an unusually warm Wednesday, a 21-year-old employee made a phone call to a supervisor at the $2 billion food startup's Bay Area fulfillment center, where tens of thousands of meal kits are packed into cardboard containers and shipped across the continental United States. The supervisor didn&039;t pick up the phone that morning, so he left a message.

In it, he said he planned to quit his job at Blue Apron later that day. He also said he planned to bring a gun to the warehouse and shoot his manager, as well as other people at the facility. In two messages, he named three people specifically who he wanted to put bullets into when he got there. Around 8:30, en route to work, the supervisor called the police.

Police apprehended the man, who did not have a gun, later that morning. But at Blue Apron, the day was just getting started.

While company security and a Richmond police officer on patrol monitored threats outside the warehouse, inside, Blue Apron management was meeting with representatives from California&039;s Division of Occupational Safety and Health at the conclusion of a two-week inspection by the agency that would result in nine violations and proposed penalties totaling $11,695 for unsafe conditions that put workers at risk for fractured bones, chemical burns, and more. This penalty came on top of $13,050 following a forklift accident earlier in the year, giving Blue Apron the most OSHA violations in the fast-growing, $5 billion meal-kit startup industry, and among the most in perishable prepared-food manufacturing in California. (Like many companies, Blue Apron appealed these findings, and had some of its violation classifications downgraded to “general” or “other.” One of its cases is still open.)

Just after 4 p.m. on the same day, the police were back at Blue Apron for the third time, following a noontime patrol. They were prompted by yet another call from a security guard, concerned that “a weapon might be brought.”

This time the problem was a 26-year-old man who, after being fired earlier in the day for groping a female co-worker, had then threatened the person who let him go. He was later arrested for sexual assault, as well as for violating his parole on an earlier robbery charge.

“I definitely remember that day,” said David Reifschneider, who was general manager of the facility at the time. “It&039;s not what happens on a typical day in a typical warehouse.”

He&039;s right. This wasn’t a typical day, nor was it a typical old-fashioned warehouse, but the thrumming hub of a fast-growing, well-funded, hugely ambitious food startup. Founded in New York City in 2012, Blue Apron now operates fulfillment centers in Richmond, where the vast majority of the workers interviewed for this article worked, as well as Jersey City and Arlington, Texas. Between them and the company’s corporate headquarters in New York City, Blue Apron employs more than 4,000 people and delivers around 8 million meals every month all over the continental United States. It has raised $193.8 million in venture capital, and in 2015 it was valued at $2 billion; if the Silicon Valley rumor mill can be believed, the company could go public in the next year, with an additional billion dollars tacked on to that valuation. The Richmond facility alone grew from fewer than 50 employees in 2014 to over 1,000 today, making Blue Apron one of the largest employers in the city.

But scaling a manufacturing facility in a historically crime-dogged city like Richmond as fast as if it were a downtown San Francisco software firm hasn’t been easy for Blue Apron. The company has set out to upend the entrenched industrial food system and disrupt the dinner table by changing the way Americans buy, receive, and prepare food, reducing food waste and increasing distribution and delivery efficiencies in the process. To do that, it had to rapidly hire a massive unskilled workforce, bringing jobs to a part of the Bay Area that has been largely left behind by Silicon Valley’s boom times. Yet documents and interviews suggest that it was unprepared to properly manage and care for those workers, and as a result has suffered a rash of health and safety violations.

In the 38 months since Blue Apron&039;s facility opened, the Richmond Police Department has received calls from there twice because of weapons, three times for bomb threats, and seven times because of assault. Police captains have met twice with Blue Apron to discuss the frequency of calls to the police. At least four arrests have been made due to violence on the premises, or threats of it. Employees have reported being punched in the face, choked, groped, pushed, pulled, and even bitten by each other on the job, according to police reports. Employees recalled bomb scares, brandished kitchen knives, and talk of guns.

All told, interviews with 14 former employees describe a chaotic, stressful environment where employees work long days for wages starting at $12 an hour bagging cilantro or assembling boxes in a warehouse kept at a temperature below 40 degrees.

“You put honey in a small container. We would put small peppers in little small bags,” said Glenn Lovely, who worked as a temp in the Richmond facility for three months. “And it was cold — cold as hell.”

Scaling a manufacturing facility in a historically crime-dogged city like Richmond as fast as if it were a downtown San Francisco software firm hasn’t been easy for Blue Apron.

To combat the cold temperatures required by food safety laws, Blue Apron provides each employee with a jacket, thermals, a hat, and a neck warmer. Some people said this was sufficient, but others struggled to adjust. “Your fingers would start to get numb and start to hurt from using them,” said former warehouse lead Andrew Driskell.

One person said Blue Apron was the worst job she&039;d ever had. Others said it wasn’t so bad. But every one of them — even those who mostly liked the job — recalled violence or threats of violence, visits from the police, injuries, high turnover, unfair treatment, or a combination of the above.

“I enjoy jobs where things are on fire more than ones where I’m sitting around,” said one former team lead of his experience at Blue Apron. “But there were times when it was just horrible.”

Blue Apron declined to make an executive available for an interview. In a statement to BuzzFeed News, the company stressed its commitment to “creating the best possible workplace experience for all of our employees. We are proud of our corporate culture and the good work that our employees do every day, bringing families across the country together over delicious, home-cooked meals.”

The idea, on its surface, is simple. Once a week, customers receive a box in the mail with recipe cards and all the pre-portioned, farm-fresh ingredients — down to tablespoonfuls of vinegar and sprigs of oregano — needed to make two, three, or four wholesome, healthy, Instagram-ready, home-cooked meals. The cost per plate is just under $10, and each meal takes an average of 35 minutes to prepare (or so the recipe cards claim). As the sales pitch goes, it’s healthier than takeout, easier than cooking from scratch, and cheaper than a private chef or meal delivery service. Blue Apron’s product is, essentially, hired help in the kitchen at a fraction of the cost — a way for busy professionals and rural foodies to whip up meals like skokichi squash ragù and mafalda pasta with mushrooms, garlic chives, and rosemary or crispy catfish with kale-farro salad and warm grape relish in less than an hour, without setting foot in a grocery store or planning a meal. Its popularity has made the company a rising star among a new class of Silicon Valley disruptors whose product is not software, but real-world products, delivered to your door frictionlessly, quickly, efficiently, and sometimes inexpensively, with just a few clicks of a mouse or taps of an app.

Matthew Mead / AP

“I think that there is a great opportunity today to create, through technology, a leaner food system that cuts out the various steps between the consumer and supplier,” company co-founder Matt Wadiak said in an August Q&A with the nonprofit Food Tank. Words like “sustainable” and “responsible” pepper the company’s website, which features high-resolution photos of happy cheesemakers and sun-baked farms.

But between farm and front door is the massive, mostly invisible process by which all those ingredients are measured, cut, prepped, bagged, packed, palletized, and shipped. For all its outward simplicity, Blue Apron’s business model is predicated on a hugely complicated feat of precision logistics, executed at an enormous volume. Each week, the company has to develop 10 original, relatively healthy, widely appealing, geographically and seasonally appropriate recipes that can be prepared easily and quickly, with ingredients that are affordable and available at scale. It has to source correct quantities of produce, meat, cheese, bread, spices, and staples from “artisanal purveyors and hundreds of family-run farms” across the country. And then it has to precisely portion and package each of those ingredients — 10 to 12 per meal in this week’s boxes — and send them out to hundreds of thousands of people, ideally without breakage, spoiling, lost packages, or missing ingredients. While the USDA estimates that 10% of food produced in the US is wasted at the retail level, Blue Apron aims to waste just 3% of the food it purchases. If it’s successful, Blue Apron will have done something no one else has, and save a boatload of money in the process.

Blue Apron’s Richmond facility opened in August 2013. In June 2014, the company posted that it was hiring 400 people there; the next 18 months would see a period of rapid growth. David Reifschneider, who has worked for Walmart, Amazon, and Zulily, was hired in May 2015 to be the general manager of the Richmond warehouse. That same month, Blue Apron announced the opening of its Texas facility. In June, the company raised $135 million to strengthen its supply chain. In the months leading up the chaos of August 26, 2015, it expanded its original 30,000-square-foot Richmond facility into an adjacent warehouse space. In a statement, the company attributed this period of expansion to “exceptionally high, unanticipated demand for our product.”

“When I interviewed with Blue Apron, they were doing 6,500 boxes a week,” said Sara Custer, who became head of West Coast operations in May 2014. “When I started, three weeks later, they were doing 9,000 a week. When I left, they were doing easily 20,000 out of the Richmond facility alone.”

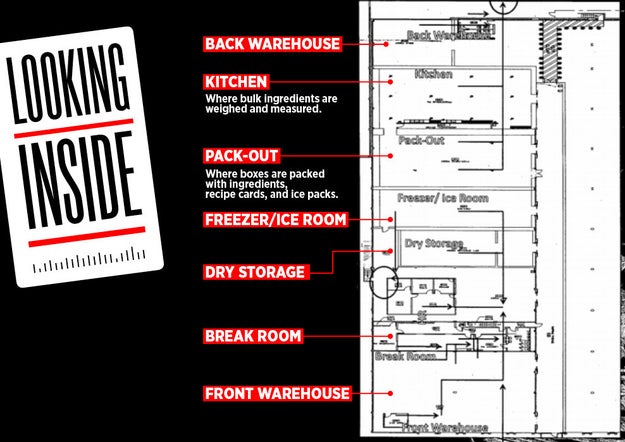

Rita Childs worked for a year and a half on the Blue Apron assembly line in the pack-out division, where boxes are filled with ice packs, recipe cards, and the appropriate ingredients for every meal. Those ingredients are prepped by kitchen associates, who weigh out and perfectly portion bulk ingredients from Blue Apron’s suppliers into small plastic bottles and bags: tablespoons of soy sauce poured into tiny bottles, for example, or carefully counted fingerling potatoes put into boxes. And after the boxes are assembled, the shipping department loads them onto pallets and, ultimately, trucks.

BuzzFeed News; Source: Cal/OSHA

By the time Childs left Blue Apron in August 2015, she said, the number of boxes being shipped per week had shot up to 34,000. “Everything that goes in the box had to be prepped 34,000 times.” When the prepping and packing was done — sometimes with the help of automated sealing and bagging equipment — shipping associates would palletize the boxes and load them onto trucks.

Flexibility and convenience are central to the Blue Apron pitch: Boxes can be canceled or modified up to about a week before the delivery day. That’s a boon for the customer, but it makes sourcing difficult, especially for a company mission-driven to reduce waste. With hundreds of thousands of people expecting dinner to be delivered on time, there’s little margin for error. “There were plenty of times where the kitchen would say we had 2,000 celery, but we actually had zero,” one former team lead told BuzzFeed News. “So we&039;d run around like chickens with our heads cut off looking for celery.”

Purchasers described scrambling to find more of a certain ingredient when supply was unexpectedly low.

“I would get sent to Whole Foods and buy things if we really needed an ingredient and we didn’t have it in the building,” said the former team lead. Blue Apron told BuzzFeed News that while during early days it sourced some of its product from local stores, the company’s shipments have been too large to make grocery store shopping feasible “for years now.”

Still, two years later, former employees recall a hectic pace. “One day in pack-out could be worse than an entire Black Friday at Best Buy, as far as stress goes,” the team lead added. Another said it wasn’t uncommon to see someone quit on their first day.

“It was crazy. You felt like you were running all the time. Your hair&039;s on fire and you can&039;t keep up,” said Custer.

“There were plenty of times where the kitchen would say we had 2,000 celery, but we actually had zero. So we&039;d run around like chickens with our heads cut off looking for celery.”

Quelle: <a href="The Not-So-Wholesome Reality Behind The Making Of Your Meal Kit“>BuzzFeed

Published by